vickers hardness test load for aluminium|brinell hardness chart for aluminum : suppliers The Vickers test uses a diamond pyramid-shaped indenter that presses into the material under a specific load. The Vickers hardness value (HV) is determined by measuring the diagonal of . web1. 2. 1. Grid. Noelle Silva Footjob Animation. 0. Added: Like (83) 6. Welcome to the biggest collection of Black Clover Hentai Flash Games Exclusive pictures, videos and games .

{plog:ftitle_list}

5 de jan. de 2001 · This is the goal statistic of FC Chelsea player Mykhaylo Mudryk, which gives a detailed view on the goals the player has scored.

1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness testing machines (Part .The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials.The Vickers test uses a diamond pyramid-shaped indenter that presses into the material under a specific load. The Vickers hardness value (HV) is determined by measuring the diagonal of .A Vickers hardness tester should be calibrated to meet ASTM standard E10 specifications, acceptable for use over a loading range. Reference: ASTM E92-17, Standard Test Methods for Vickers Hardness and Knoop Hardness of .

Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating .Find an overview of the Vickers methods and their applications depending on the load range as well as an explanation how to choose the right test load.

The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. .The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or .

Vickers Hardness (Mean±SD) Empty Cell: Before grinding After grinding; Curtis et al., 2006: Lava frame: Specimens randomly selected and submitted to a Vickers hardness test with a diamond pyramid head of a Duramin-1 Vickers hardness tester (Struers) under a predetermined load (9.807 N) over 15 s to induce a diamond-shaped indent. The size of . The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard .

Depending on the magnitude of the test force according to ISO standard (and hence on the Vickers Method, e.g.: HV 0.01; HV 1; HV 10), the Vickers process can be subdivided into three hardness testing load ranges: in the micro, low-load and conventional (macro) hardness range.Hard anodised parts are tested for hardness using the Vickers test. On average, hard anodised aluminium 6082 can achieve values in the range of 300 to 500 HV, to put that into perspective, in its untreated state it has a hardness range of 80-95 HV. . P is the depth of the indenter penetration under minor load; A is a constant factor specific .Download scientific diagram | Vickers hardness test: data on aluminum alloy. from publication: Indentation modulus at the macro-scale level measured by Brinell and Vickers indenters by using the .

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article. Specimens (Hardened steel, Mild steel, Brass, Copper, Aluminium . static and dynamic load. Hardness is the p roperty of th . of the given Specimen using Vickers hardness test.IV. Hardness Test Methods for Aluminum Hardness. Here are some of the most common hardness tests used in the industry to ascertain the hardness of Aluminum. Brinell Hardness Test. This test uses an indenter with huge loads making it suitable for very thick, large, and rough-grained material surfaces.

Vickers hardness with very small load, the load is 5-200gf. Indicated by Hm, it can be used to test the hardness of single grain or phase. Vickers hardness testThe Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials with low hardness. For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

Experimental test of hardness of aluminum and cast iron material has been done using indentor method (vickers test) with variation of indenter load on each material tested. . Vickers, gunakan load 50,100,200. JURNAL MER-C NO. 10/VOL. 1/2018 Set Dwell Time (lama waktu penjejakan beban indentor pada material uji) dengan

The Vickers hardness test measures material hardness by determining the size of an indentation made by a diamond pyramid-shaped indenter under a specific load. A load ranging from 1 gf to 100 kgf is applied to the material’s surface, creating a . Rockwell is often used for steel, aluminum, any other metals, plastics, or ceramics. . Materials that fall into a very high hardness scale or thin and small components tend to be better suited for Knoop or Vickers testing. .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test . We explore the Difference Between Vickers and Knoop hardness test ,and when each test is best suited for specific applications. 713-827-0700 . [email protected] . Knoop indentations are smaller and more elongated .VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads.

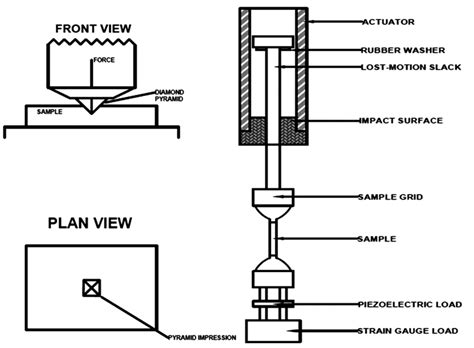

vickers hardness testing machine diagram

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . High Load: Lower Load: The Brinell hardness testing method is a comparatively slow method. So, the method is time-consuming. . Vickers Hardness (HV)- Diamond Pyramid 120 Kg: Approx. Tensile strength .specimen's surface. The Vickers hardness test is a happy medium between the two previously mentioned hardness tests, tackling both the macro and micro hardness scales. With applied loads ranging anywhere from 1𝑘 to 100𝑘 , this hardness test utilizes the vertex point of the diamond side of a square pyramidA powerful Vickers, Knoop, Brinell and Rockwell hardness testing machine, the DuraVersa-100 gives you micro, macro and universal testing in one fully automatic machine – with a wide load range and many applications, including Jominy testing, for the ultimate in versatility.

All information about the Vickers hardness test Test procedure Sample request for the Vickers method Vickers hardness Hardness Discover now. . The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load .

Application of Load. The Vickers hardness tester applies a precisely controlled load to a diamond indenter, typically in the range of a few kilograms-force to several tens of kilograms-force. . Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and . 3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. The Vickers hardness value (HV) is calculated by dividing the load by the surface area of the indentation pit, expressed in kgf/mm². 4. Leeb Hardness (HLD) The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being tested. . Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding . Vickers hardness tests were conducted on samples of copper and aluminium in a cold rolled or annealed condition to determine the apparent hardness variation in the load range 15 g to 20 kg. The variation was greatest for the soft specimens. Lubrication with an extreme-pressure lubricant was effective in reducing the hardness values to a virtually constant level .

Vickers hardness test sangat ideal untuk pengujian semua logam dan karenanya merupakan metode dengan rentang aplikasi terluas.Hardness test method menurut Vickers dijelaskan dalam standar ISO 6507 (Bahan logam – Uji kekerasan Vickers – Bagian 1: Metode uji) dan ASTM E384 (Metode Uji Standar untuk Kekerasan Mikroindentasi Bahan terhadap Vickers .

wholesale cobb sample cutter manufacturers

wholesale cobb sample cutter supplier

WEBWe would like to show you a description here but the site won’t allow us.

vickers hardness test load for aluminium|brinell hardness chart for aluminum